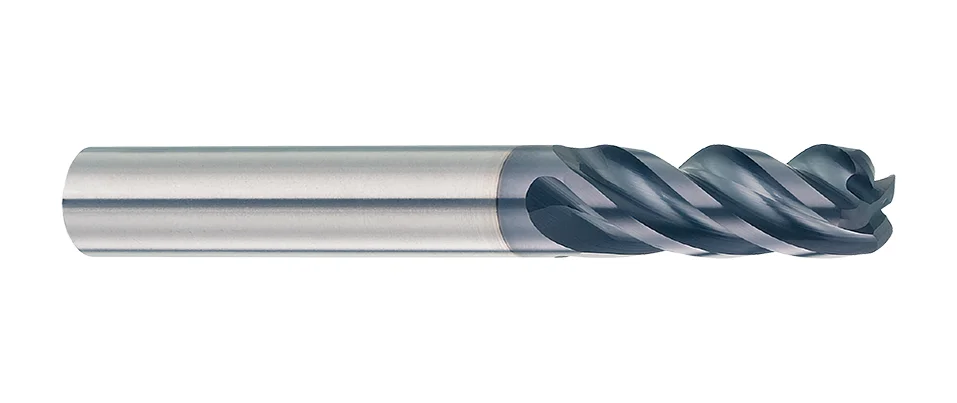

B252-2.5HX Multipurpose End Mills With Corner Radius

METRIC

ASIA

- Multipurpose End Mills with corner radius- 4 Flutes

- With UMG carbide material, wear resistance is highly enhanced.

- Effectively decrease the vibration by various helix geometry and unequal flutes designs.

- Big chip breaker is designed to reach high removal rate for various work materials.

- Obviously improve tool life with Nano multilayer coating AlTiCrN.

- Cutting edge with corner radius desgin increases tool life.

- Suitable for various kinds of work materials from the end of roughing to finishing.

Steel < 56HRC

| P | H | M | K | N | S |

|---|---|---|---|---|---|

Work Material

| P | H | M | K | S | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GR1 | GR2 | GR3 | GR4 | GR5 | GR6 | GR8 | GR9 | GR15 | GR16 | GR17 |

| Carbon Steel | <24HRC Low-alloyed Steel | <30HRC Hi-alloyed Steel | 30~38HRC Hardened Steel | 38~48HRC Hardened Steel | 48~56HRC Hardened Steel | Stainless Steel | Cast Iron | Titanium | Nickel | High Temp Alloys |

Product Specification

| Dc | R | Lc | L | d | z |

|---|---|---|---|---|---|

| 0-0.02 | ±0.01 | mm | mm | h6 | |

| 1 | R0.1 | 2.5 | 50 | 4 | 4 |

| 1 | R0.2 | 2.5 | 50 | 4 | 4 |

| 1 | R0.3 | 2.5 | 50 | 4 | 4 |

| 1.5 | R0.1 | 3.75 | 50 | 4 | 4 |

| 1.5 | R0.2 | 3.75 | 50 | 4 | 4 |

| 1.5 | R0.3 | 3.75 | 50 | 4 | 4 |

| 2 | R0.1 | 5 | 50 | 4 | 4 |

| 2 | R0.2 | 5 | 50 | 4 | 4 |

| 2 | R0.3 | 5 | 50 | 4 | 4 |

| 2 | R0.5 | 5 | 50 | 4 | 4 |

| 2.5 | R0.1 | 6.25 | 50 | 4 | 4 |

| 2.5 | R0.2 | 6.25 | 50 | 4 | 4 |

| 2.5 | R0.3 | 6.25 | 50 | 4 | 4 |

| 2.5 | R0.5 | 6.25 | 50 | 4 | 4 |

| 3 | R0.1 | 7.5 | 50 | 6 | 4 |

| 3 | R0.2 | 7.5 | 50 | 6 | 4 |

| 3 | R0.3 | 7.5 | 50 | 6 | 4 |

| 3 | R0.4 | 7.5 | 50 | 6 | 4 |

| 3 | R0.5 | 7.5 | 50 | 6 | 4 |

| 4 | R0.1 | 10 | 50 | 6 | 4 |

| 4 | R0.2 | 10 | 50 | 6 | 4 |

| 4 | R0.3 | 10 | 50 | 6 | 4 |

| 4 | R0.4 | 10 | 50 | 6 | 4 |

| 4 | R0.5 | 10 | 50 | 6 | 4 |

| 4 | R1 | 10 | 50 | 6 | 4 |

| 5 | R0.2 | 12.5 | 50 | 6 | 4 |

| 5 | R0.3 | 12.5 | 50 | 6 | 4 |

| 5 | R0.4 | 12.5 | 50 | 6 | 4 |

| 5 | R0.5 | 12.5 | 50 | 6 | 4 |

| 5 | R1 | 12.5 | 50 | 6 | 4 |

| 6 | R0.2 | 15 | 50 | 6 | 4 |

| 6 | R0.3 | 15 | 50 | 6 | 4 |

| 6 | R0.4 | 15 | 50 | 6 | 4 |

| 6 | R0.5 | 15 | 50 | 6 | 4 |

| 6 | R0.8 | 15 | 50 | 6 | 4 |

| 6 | R1 | 15 | 50 | 6 | 4 |

| 6 | R1.2 | 15 | 50 | 6 | 4 |

| 6 | R1.5 | 15 | 50 | 6 | 4 |

| 6 | R1.6 | 15 | 50 | 6 | 4 |

| 6 | R2 | 15 | 50 | 6 | 4 |

| 7 | R0.2 | 17.5 | 60 | 8 | 4 |

| 7 | R0.3 | 17.5 | 60 | 8 | 4 |

| 7 | R0.4 | 17.5 | 60 | 8 | 4 |

| 7 | R0.5 | 17.5 | 60 | 8 | 4 |

| 7 | R1 | 17.5 | 60 | 8 | 4 |

| 8 | R0.2 | 20 | 60 | 8 | 4 |

| 8 | R0.3 | 20 | 60 | 8 | 4 |

| 8 | R0.4 | 20 | 60 | 8 | 4 |

| 8 | R0.5 | 20 | 60 | 8 | 4 |

| 8 | R0.8 | 20 | 60 | 8 | 4 |

| 8 | R1 | 20 | 60 | 8 | 4 |

| 8 | R1.2 | 20 | 60 | 8 | 4 |

| 8 | R1.5 | 20 | 60 | 8 | 4 |

| 8 | R1.6 | 20 | 60 | 8 | 4 |

| 8 | R2 | 20 | 60 | 8 | 4 |

| 8 | R3 | 20 | 60 | 8 | 4 |

| 9 | R0.2 | 22.5 | 72 | 10 | 4 |

| 9 | R0.3 | 22.5 | 72 | 10 | 4 |

| 9 | R0.4 | 22.5 | 72 | 10 | 4 |

| 9 | R0.5 | 22.5 | 72 | 10 | 4 |

| 9 | R1 | 22.5 | 72 | 10 | 4 |

| 10 | R0.2 | 25 | 72 | 10 | 4 |

| 10 | R0.3 | 25 | 72 | 10 | 4 |

| 10 | R0.4 | 25 | 72 | 10 | 4 |

| 10 | R0.5 | 25 | 72 | 10 | 4 |

| 10 | R0.8 | 25 | 72 | 10 | 4 |

| 10 | R1 | 25 | 72 | 10 | 4 |

| 10 | R1.2 | 25 | 72 | 10 | 4 |

| 10 | R1.5 | 25 | 72 | 10 | 4 |

| 10 | R1.6 | 25 | 72 | 10 | 4 |

| 10 | R2 | 25 | 72 | 10 | 4 |

| 10 | R3 | 25 | 72 | 10 | 4 |

| 11 | R0.2 | 27.5 | 75 | 12 | 4 |

| 11 | R0.3 | 27.5 | 75 | 12 | 4 |

| 11 | R0.4 | 27.5 | 75 | 12 | 4 |

| 11 | R0.5 | 27.5 | 75 | 12 | 4 |

| 11 | R1 | 27.5 | 75 | 12 | 4 |

| 12 | R0.2 | 30 | 75 | 12 | 4 |

| 12 | R0.3 | 30 | 75 | 12 | 4 |

| 12 | R0.4 | 30 | 75 | 12 | 4 |

| 12 | R0.5 | 30 | 75 | 12 | 4 |

| 12 | R0.8 | 30 | 75 | 12 | 4 |

| 12 | R1 | 30 | 75 | 12 | 4 |

| 12 | R1.2 | 30 | 75 | 12 | 4 |

| 12 | R1.5 | 30 | 75 | 12 | 4 |

| 12 | R1.6 | 30 | 75 | 12 | 4 |

| 12 | R2 | 30 | 75 | 12 | 4 |

| 12 | R3 | 30 | 75 | 12 | 4 |

| 13 | R0.5 | 32.5 | 100 | 16 | 4 |

| 13 | R1 | 32.5 | 100 | 16 | 4 |

| 13 | R1.5 | 32.5 | 100 | 16 | 4 |

| 13 | R2 | 32.5 | 100 | 16 | 4 |

| 13 | R3 | 32.5 | 100 | 16 | 4 |

| 14 | R0.5 | 35 | 100 | 16 | 4 |

| 14 | R1 | 35 | 100 | 16 | 4 |

| 14 | R1.5 | 35 | 100 | 16 | 4 |

| 14 | R2 | 35 | 100 | 16 | 4 |

| 14 | R3 | 35 | 100 | 16 | 4 |

| 15 | R0.5 | 37.5 | 100 | 16 | 4 |

| 15 | R1 | 37.5 | 100 | 16 | 4 |

| 15 | R1.5 | 37.5 | 100 | 16 | 4 |

| 15 | R2 | 37.5 | 100 | 16 | 4 |

| 15 | R3 | 37.5 | 100 | 16 | 4 |

| 16 | R0.5 | 40 | 100 | 16 | 4 |

| 16 | R1 | 40 | 100 | 16 | 4 |

| 16 | R1.5 | 40 | 100 | 16 | 4 |

| 16 | R2 | 40 | 100 | 16 | 4 |

| 16 | R3 | 40 | 100 | 16 | 4 |

| 16 | R4 | 40 | 100 | 16 | 4 |

| 17 | R0.5 | 42.5 | 100 | 20 | 4 |

| 17 | R1 | 42.5 | 100 | 20 | 4 |

| 17 | R1.5 | 42.5 | 100 | 20 | 4 |

| 17 | R2 | 42.5 | 100 | 20 | 4 |

| 17 | R3 | 42.5 | 100 | 20 | 4 |

| 18 | R0.5 | 45 | 100 | 20 | 4 |

| 18 | R1 | 45 | 100 | 20 | 4 |

| 18 | R1.5 | 45 | 100 | 20 | 4 |

| 18 | R2 | 45 | 100 | 20 | 4 |

| 18 | R3 | 45 | 100 | 20 | 4 |

| 19 | R0.5 | 47.5 | 100 | 20 | 4 |

| 19 | R1 | 47.5 | 100 | 20 | 4 |

| 19 | R1.5 | 47.5 | 100 | 20 | 4 |

| 19 | R2 | 47.5 | 100 | 20 | 4 |

| 19 | R3 | 47.5 | 100 | 20 | 4 |

| 20 | R0.5 | 50 | 100 | 20 | 4 |

| 20 | R1 | 50 | 100 | 20 | 4 |

| 20 | R1.5 | 50 | 100 | 20 | 4 |

| 20 | R2 | 50 | 100 | 20 | 4 |

| 20 | R3 | 50 | 100 | 20 | 4 |

| 20 | R4 | 50 | 100 | 20 | 4 |

| 20 | R5 | 50 | 100 | 20 | 4 |