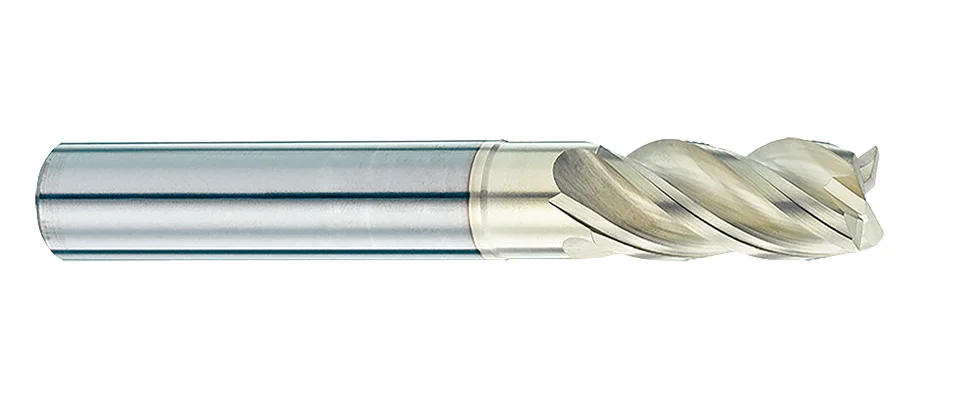

F651SX End Mills For Difficult To Cut Materials

METRIC

DIN

- Designed with two variable helix geometry and two unequal flutes.

- Sharp cutting edge is good for cutting toughness materials.

- Designed with high removal cutting geometry.

- Good wear resistance and lubricating effect with Nano multilayer coating.

- Sharp cutting edge is suitable for cutting stainless steel, titanium, nickel and high temp alloys… etc.

- Application for roughing and finishing cutting in different materials.

- ※Tools with side lock is available.

Stainless, Titanium, Nickle

| P | H | M | K | N | S |

|---|---|---|---|---|---|

Work Material

| P | H | M | S | |||||

|---|---|---|---|---|---|---|---|---|

| GR1 | GR2 | GR3 | GR4 | GR5 | GR8 | GR15 | GR16 | GR17 |

| Carbon Steel | <24HRC Low-alloyed Steel | <30HRC Hi-alloyed Steel | 30~38HRC Hardened Steel | 38~48HRC Hardened Steel | Stainless Steel | Titanium | Nickel | High Temp Alloys |

Product Specification

| Dc | Lc | L | d | L1 | D1 | 45゜ | z |

|---|---|---|---|---|---|---|---|

| 0 -0.02 | mm | mm | h5 | mm | mm | mm | |

| 3 | 8 | 57 | 6 | 14 | 2.8 | 0.1 | 4 |

| 4 | 11 | 57 | 6 | 16 | 3.8 | 0.1 | 4 |

| 5 | 13 | 57 | 6 | 18 | 4.8 | 0.15 | 4 |

| 6 | 13 | 57 | 6 | 20 | 5.8 | 0.15 | 4 |

| 8 | 19 | 63 | 8 | 26 | 7.7 | 0.15 | 4 |

| 10 | 22 | 72 | 10 | 31 | 9.7 | 0.2 | 4 |

| 12 | 26 | 83 | 12 | 37 | 11.6 | 0.2 | 4 |

| 16 | 32 | 92 | 16 | 43 | 15.5 | 0.2 | 4 |

| 20 | 38 | 104 | 20 | 53 | 19.5 | 0.2 | 4 |