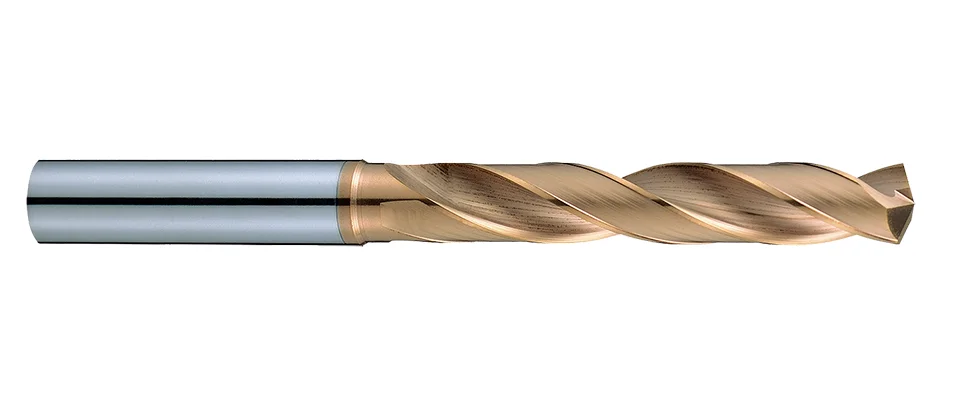

D422TX High Performance Drills

METRIC

ASIA

- JIS 5XD Drills

- 140° S-shape drill tip design to reduce axial force.

- Design with groove shape to provide higher chip removal rates.

- Good wear resistance and lubrication with Nano multilayer coating.

- Application for drilling with Steels which under HRC48, Cast Iron, Aluminium…etc.

- Suitable for drilling with 5XD depth.

Steel < 48HRC

| P | H | M | K | N | S |

|---|---|---|---|---|---|

Work Material

| P | H | M | K | S | |||||

|---|---|---|---|---|---|---|---|---|---|

| GR1 | GR2 | GR3 | GR4 | GR5 | GR8 | GR9 | GR15 | GR16 | GR17 |

| Carbon Steel | <24HRC Low-alloyed Steel | <30HRC Hi-alloyed Steel | 30~38HRC Hardened Steel | 38~48HRC Hardened Steel | Stainless Steel | Cast Iron | Titanium | Nickel | High Temp Alloys |

Product Specification

| Dc | Lc | L | d |

|---|---|---|---|

| h7 | mm | mm | h6 |

| 1 | 12 | 62 | 3 |

| 1.1 | 12 | 62 | 3 |

| 1.2 | 12 | 62 | 3 |

| 1.3 | 12 | 62 | 3 |

| 1.4 | 12 | 62 | 3 |

| 1.5 | 12 | 62 | 3 |

| 1.6 | 15 | 62 | 3 |

| 1.7 | 15 | 62 | 3 |

| 1.8 | 15 | 62 | 3 |

| 1.9 | 15 | 62 | 3 |

| 2 | 15 | 62 | 3 |

| 2.1 | 18 | 66 | 3 |

| 2.2 | 18 | 66 | 3 |

| 2.3 | 18 | 66 | 3 |

| 2.4 | 18 | 66 | 3 |

| 2.5 | 18 | 66 | 3 |

| 2.6 | 20 | 66 | 3 |

| 2.7 | 20 | 66 | 3 |

| 2.8 | 20 | 66 | 3 |

| 2.9 | 20 | 66 | 3 |

| 3 | 20 | 66 | 3 |

| 3.1 | 24 | 74 | 4 |

| 3.2 | 24 | 74 | 4 |

| 3.3 | 24 | 74 | 4 |

| 3.4 | 24 | 74 | 4 |

| 3.5 | 24 | 74 | 4 |

| 3.6 | 28 | 74 | 4 |

| 3.7 | 28 | 74 | 4 |

| 3.8 | 28 | 74 | 4 |

| 3.9 | 28 | 74 | 4 |

| 4 | 28 | 74 | 4 |

| 4.1 | 32 | 74 | 5 |

| 4.2 | 32 | 74 | 5 |

| 4.3 | 32 | 74 | 5 |

| 4.4 | 32 | 74 | 5 |

| 4.5 | 32 | 74 | 5 |

| 4.6 | 38 | 74 | 5 |

| 4.7 | 38 | 74 | 5 |

| 4.8 | 38 | 74 | 5 |

| 4.9 | 38 | 74 | 5 |

| 5 | 38 | 74 | 5 |

| 5.1 | 44 | 82 | 6 |

| 5.2 | 44 | 82 | 6 |

| 5.3 | 44 | 82 | 6 |

| 5.4 | 44 | 82 | 6 |

| 5.5 | 44 | 82 | 6 |

| 5.6 | 44 | 82 | 6 |

| 5.7 | 44 | 82 | 6 |

| 5.8 | 44 | 82 | 6 |

| 5.9 | 44 | 82 | 6 |

| 6 | 44 | 82 | 6 |

| 6.1 | 53 | 91 | 7 |

| 6.2 | 53 | 91 | 7 |

| 6.3 | 53 | 91 | 7 |

| 6.4 | 53 | 91 | 7 |

| 6.5 | 53 | 91 | 7 |

| 6.6 | 53 | 91 | 7 |

| 6.7 | 53 | 91 | 7 |

| 6.8 | 53 | 91 | 7 |

| 6.9 | 53 | 91 | 7 |

| 7 | 53 | 91 | 7 |

| 7.1 | 53 | 91 | 8 |

| 7.2 | 53 | 91 | 8 |

| 7.3 | 53 | 91 | 8 |

| 7.4 | 53 | 91 | 8 |

| 7.5 | 53 | 91 | 8 |

| 7.6 | 53 | 91 | 8 |

| 7.7 | 53 | 91 | 8 |

| 7.8 | 53 | 91 | 8 |

| 7.9 | 53 | 91 | 8 |

| 8 | 53 | 91 | 8 |

| 8.1 | 61 | 103 | 9 |

| 8.2 | 61 | 103 | 9 |

| 8.3 | 61 | 103 | 9 |

| 8.4 | 61 | 103 | 9 |

| 8.5 | 61 | 103 | 9 |

| 8.6 | 61 | 103 | 9 |

| 8.7 | 61 | 103 | 9 |

| 8.8 | 61 | 103 | 9 |

| 8.9 | 61 | 103 | 9 |

| 9 | 61 | 103 | 9 |

| 9.1 | 61 | 103 | 10 |

| 9.2 | 61 | 103 | 10 |

| 9.3 | 61 | 103 | 10 |

| 9.4 | 61 | 103 | 10 |

| 9.5 | 61 | 103 | 10 |

| 9.6 | 61 | 103 | 10 |

| 9.7 | 61 | 103 | 10 |

| 9.8 | 61 | 103 | 10 |

| 9.9 | 61 | 103 | 10 |

| 10 | 61 | 103 | 10 |

| 10.1 | 71 | 118 | 11 |

| 10.2 | 71 | 118 | 11 |

| 10.3 | 71 | 118 | 11 |

| 10.4 | 71 | 118 | 11 |

| 10.5 | 71 | 118 | 11 |

| 10.6 | 71 | 118 | 11 |

| 10.7 | 71 | 118 | 11 |

| 10.8 | 71 | 118 | 11 |

| 10.9 | 71 | 118 | 11 |

| 11 | 71 | 118 | 11 |

| 11.1 | 71 | 118 | 12 |

| 11.2 | 71 | 118 | 12 |

| 11.3 | 71 | 118 | 12 |

| 11.4 | 71 | 118 | 12 |

| 11.5 | 71 | 118 | 12 |

| 11.6 | 71 | 118 | 12 |

| 11.7 | 71 | 118 | 12 |

| 11.8 | 71 | 118 | 12 |

| 11.9 | 71 | 118 | 12 |

| 12 | 71 | 118 | 12 |

| 12.5 | 77 | 124 | 13 |

| 13 | 77 | 124 | 13 |

| 13.5 | 77 | 124 | 14 |

| 14 | 77 | 124 | 14 |

| 14.5 | 83 | 133 | 15 |

| 15 | 83 | 133 | 15 |

| 15.5 | 83 | 133 | 16 |

| 16 | 83 | 133 | 16 |